A Matlab algorithm developed for automatic layout generation of thin film heaters

Thermal control is the essence of many chemical processes in LOC. Distributing temperatures precisely in the micro-scale, however, is extremely complex. At UofA we developed a method that enables fast design of system-customized thin film heaters for precise spatial temperature control in planar structures of any size and shape. Only a single layer of conductive material is necessary to produce the desired temperature profile. The method allows for maximizing energy efficiency and minimizing the heater footprint. Owing ot its non-iterative nature, the method is capable of generating an optimal heater design in few minutes automatically. The method also enabled the fabrication of aluminum thin film heaters/sensors, replacing expensive metals like platinum or gold, commonly used in LOC. The use of aluminum opened the possibility of integrating a full LOC system onto a CMOS die that could be packaged in a USB key.

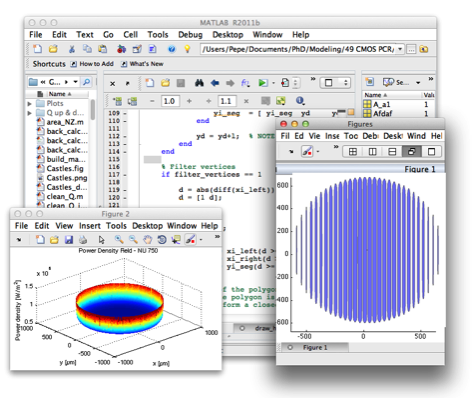

At the heart of the method is an algorithm written in Matlab that is inspired in the finite element method. The algorithm divides the pre-determined power density field of the heater into small segments and for each segment computes the width of the track piece that meets the required power. Since the width is computed for each segment rather that for the entire geometry, the size and shape of the heater can be arbitrary. Since the segment size is free-to-choose, very high resolution power density fields can be achieved, only limited by fabrication constraints.

Thermal control is the essence of many chemical processes in LOC. Distributing temperatures precisely in the micro-scale, however, is extremely complex. At UofA we developed a method that enables fast design of system-customized thin film heaters for precise spatial temperature control in planar structures of any size and shape. Only a single layer of conductive material is necessary to produce the desired temperature profile. The method allows for maximizing energy efficiency and minimizing the heater footprint. Owing ot its non-iterative nature, the method is capable of generating an optimal heater design in few minutes automatically. The method also enabled the fabrication of aluminum thin film heaters/sensors, replacing expensive metals like platinum or gold, commonly used in LOC. The use of aluminum opened the possibility of integrating a full LOC system onto a CMOS die that could be packaged in a USB key.

At the heart of the method is an algorithm written in Matlab that is inspired in the finite element method. The algorithm divides the pre-determined power density field of the heater into small segments and for each segment computes the width of the track piece that meets the required power. Since the width is computed for each segment rather that for the entire geometry, the size and shape of the heater can be arbitrary. Since the segment size is free-to-choose, very high resolution power density fields can be achieved, only limited by fabrication constraints.